12

Sep

Simple Guide to Mobile Crushers & Screens

People involved in the construction and mining industry are expected to encounter difficult problems when it comes to buying either mobile screen or mobile crushers. As of today, there are over 20 suppliers of mobile crushers and screens with more than 250 different models available on the Australian market. This makes the decision-making process very tough for contractors. Some of these brands are especially popular in the mobile crushing and screening Australian market, such as Kleemann, Metso, Terex and Sandvik. There are also many new-comers, which are less known to users, but offer some really fine mobile crushers and screen equipment. Read More →

01

Sep

Simple Guide To Choosing The Right Jib Crane

Today, the industry requires powerful, flexible and versatile machines, capable to handle a variety of tasks in a cost efficient manner. One category of industrial machines which are heavily used are the jib cranes. These lifting machines can be found in every major production or manufacturing facility where large and bulky items need to be lifted and moved from one location to another. A jib crane is a flexible and efficient lifting equipment that saves both time and money while increasing the productivity. It can improve the work flow and the material handling efficiency. There are different jib crane models on the market, and each model is used for specific lifting operation. Generally, there are three jib crane types: free standing jib cranes, mast type jib cranes, and wall mounted jib cranes. Although used for the same purpose, every model is different in terms of design, configuration and specifications. Read More →

01

Sep

Simple Guide to Buying a Motor Grader

One machine that is heavily used in the construction sector is the motor grader. Also known as road grader, blade or maintainer, the motor grader is actually a vehicle that has a long metal blade which is positioned between the front and rear wheels. The blade is used for grading flat surfaces. In general, the motor graders are used for creating smooth and flat surface after using bulldozers and scrapers.

The graders come in a variety of forms and sizes, and they can be found on every major construction site all over Australia. With so many graders on the market, buying the right model for your job requires attention and careful comparison. Buying a motor grader can be a complicated task because many factors need to be considered. While most graders that can be found on the market come with similar configuration and specifications, you will need to find reliable and reputable suppliers or grader manufacturers that offer machines with unique features at reasonable prices. Read More →

27

Aug

Simple Guide For Using Truck Cranes Properly

One crane model that is heavily used in many industry sectors is the truck crane. The truck cranes offer many benefits and advantages in terms of versatility and flexibility. It is generally a truck with a crane attached on the back. The excellent maneuverability is what makes the truck cranes to be extensively used in various industries, including manufacturing facilities, transportation and construction. Knowing how to properly use and operate truck cranes can make a big difference and should be imperative for all crane operators in order to maximize the productivity on the job site. If you own or plan to purchase a truck crane, read the following guide about how to properly use truck cranes.

Safety. The operators of the truck cranes have a great responsibility for the safety on the job site. They need to pay attention how they operate their machines in order to avoid damages and to prevent serious injuries to any worker near the working area. The operators work from the inside of the cabin, and therefore they must understand all controls and need to have the required skills and knowledge in order to operate the truck cranes safely and efficiently.

Proper Training And License For Operating Truck Cranes. There are some strict regulations regarding who can operate a truck crane. These regulations state that the operators of the truck cranes need to complete appropriate training program that includes both learning from books and practical exercises. After the training program, the operators earn a license for operating truck cranes.

Cabin Controls. The operators need to know how to use the controls inside in the cabin. There are generally two types of joysticks in the operator’s cab: one joystick that controls the horizontal side to side movements, and another joystick that controls the back and forward movements. There are also foot pedals that control the movements of the boom. One modern approach for operation is via radio controls. This option allows the operators to work with truck cranes by remote control outside the cabin.

Working Area Inspection. Proper and safe operation of the truck cranes is not the only consideration. It is also very important for the operators to perform a safety inspection on the working area where they are planing to use the truck crane. They need to ensure that there are no safety hazards. Before lifting a heavy load, the path needs to be cleared from any obstacles. If there are big power lines, the operators need to plan and develop a safety route in order to prevent any contact with the power lines.

19

Aug

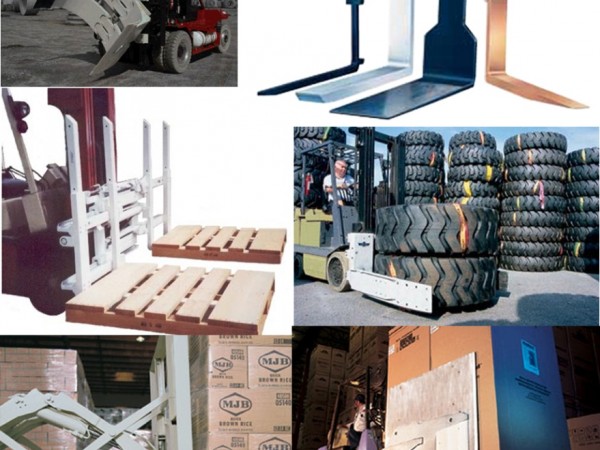

Simple Guide For Safe Forklift Attachment Operation

The forklift attachments are very important tools, because they allow the forklifts to be used for different tasks at the workplace. Many contractors and operators of forklifts think that the forklift attachments are required only for handling unique tasks or specific objects. They are wrong, because the forklift attachments are making the forklifts suitable machines for a variety of jobs.

There are various types of forklift attachments on the market, from standard attachments which are used on a daily basis, to very weird and unconventional forklift tools designed for unique purposes. Although they bring many benefits for the forklift operators, there are important safety considerations that must be known. The operators need to be well-trained and experienced of operating normal forklifts, but they also must be trained how to use different forklift attachments. Here is a simple guide for safe operation with forklift attachments: Read More →

18

Aug

Simple Guide For Saving Time And Effort By Using Excavator Attachments

The excavator is very efficient machine with a huge role in the mining and construction industry. Although mainly used as a digging machine, when equipped with different excavator attachments, the excavator can be used for a variety or tasks. The most important thing for completing a job in easy, safe and efficient way is to use the right excavator attachment for a specific job. In the past, the excavators were equipped only with buckets for digging, but today there is a wide range of different excavator attachments, even special attachments for specific operations. Here is a simple guide that can help you to save time and effort by using the right excavator attachments for any specific application. Read More →

13

Aug

Simple Guide To Franna Crane

If you are looking for a versatile and multipurpose crane that can perform various construction works, then the franna crane is all what you need. The first Franna crane was presented on the market back in 1980, and since then the Franna cranes have been used all over Australia. The Franna crane was originally developed by Dave Francis, a founder of the Franna company. The name of the company comes from Francis and Anna- the name of his daughter. It was the first pick & carry crane designed for construction sites, workshops and mines. After few years, Francis sold the company to Brian Hain and Lou Parolin, but the original design of the cranes was still used. Franna became Australia’s most popular crane brand due to its high-speed, versatility and flexibility. Years later, the American company Terex bought the brand, and the cranes were named Terex-Franna. With this acquisition, the Franna crane became popular not only in Australia and America, but also worldwide. Read More →

12

Aug

Simple Guide To Rock Breaker Safety Precautions

The operations that involve breaking or crushing large stones, rocks and other solid materials, require strong and powerful machines for efficient results. One machine that is ideal for such operations would be the rock breaker. The rock breaker is a machine designed and developed especially for the toughest breaking operations, and it is used for many applications in both construction and mining sites. It is capable to reduce the size of rocks that are too large or too heavy in a efficient and quick manner. However, the operations with a rock breaker involve some risks for the safety of the operators, and a lot of attention is required. Here are the most important safety precautions you need to know when operating a rock breaker: Read More →

12

Aug

Simple Guide For Operating Mining Machinery

The mine operations are performed in the most threatening working environments in the world. These operations include large mining machinery, hazardous gasses and possibility of landslide. Furthermore, the mining machinery can be dangerous for the operators, because they are huge and require lot of space for efficient operation. All mining equipment must be properly and safely operated, because if not, they can lead to serious accidents. The landslide possibility is always present, as well as the hazardous gasses. However, the miners can do a lot of things to protect themselves from all the threats. This simple guide contains very useful tips about how to operate a mining equipment safely and efficiently: Read More →